Griffin-Woodhouse (GWEC) was approached by a client contracted to supply umbilical clamps to an offshore floating production system (FPS). The end user was explicit in their specified use of a lifting shackle not qualified for mooring applications, which no manufacturer could offer. Therefore, GWEC was appointed to conduct analysis, requalify according to offshore mooring chain Standards and supply c/w full class certification for use on the project.

Analysis was conducted to study the structural strength of the shackle under the influence of proof load & min. break load conditions. Fatigue life estimation was based on provided load spectrum data with calculations performed using appropriates S-N curve.

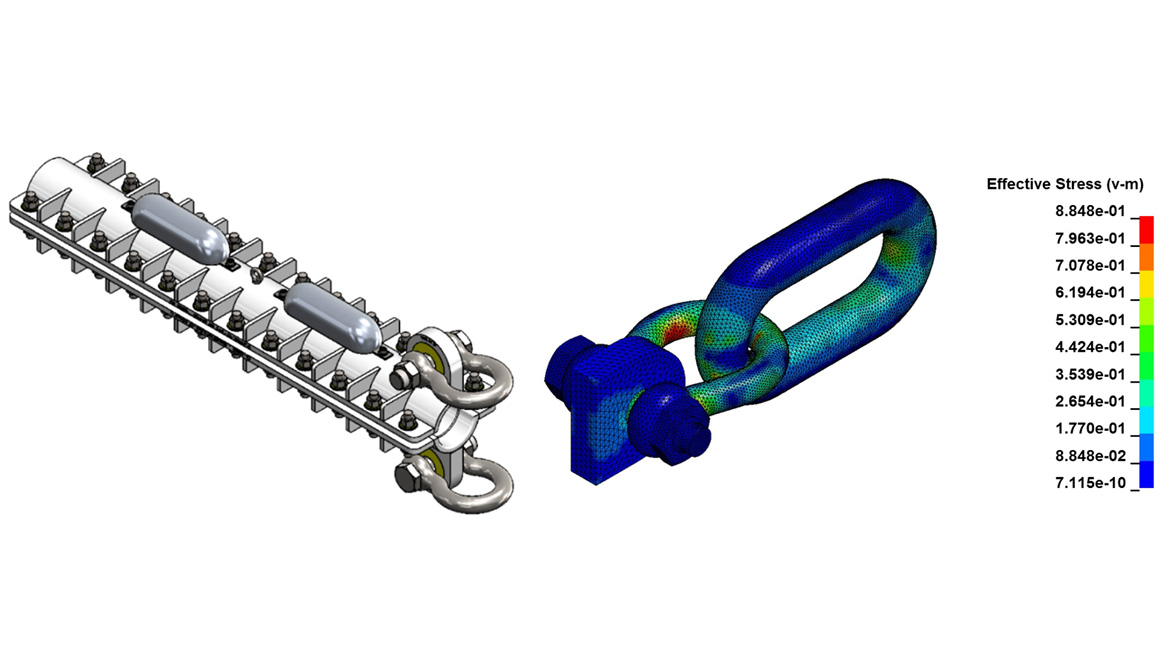

Assembly geometry was modelled in SolidWorks and translated to ANSYS using a STEP interface, where initial structural analysis was conducted. Further analysis was conducted using LS DYNA and known material stress/strain curves were used as a starting point for the simulation.

Stresses developed on the shackle were found to be safe and within material properties specified by the relevant offshore mooring chain Standard. Fatigue analysis, according to the given load spectrum, resulted in failure after 5×1017 cycles, or 253,678,335,870 years!

Consequently, design approval was granted by the relevant class agency and GWEC proceeded to complete manufacturing approval and supply a complete set of equipment for use on the project.

Griffin-Woodhouse always strives to exceed expectations, and our grateful client commented –

“GWEC was the only company able to offer this solution and solved what was becoming a massive headache for us.”

If you require quality assured products, expert advice and service that exceeds expectations, don’t hesitate to contact us.